What does it take to make a highly reliable engine? Advanced and scientific designs, gradually optimized processing technology, and mature experience in application...... these are all the key factors of high engine quality. In addition to designs, assembling processes and applications, it is also crucial that the engine has the strongest flesh and bones.

All of the above are inseparable from the high-quality casting products with the superb level.

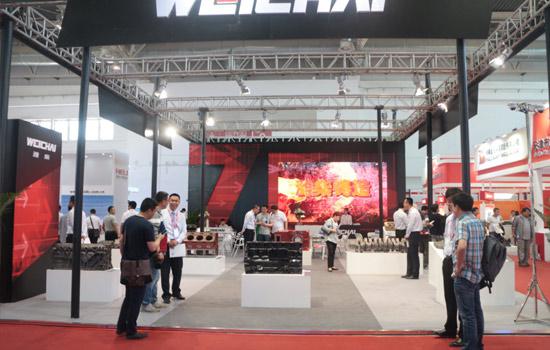

At the 14th China International Foundry Fair opened on May 17, Weichai demonstrated its environmental and technically leading casting products, not only to spread the "Green Weichai" manufacturing philosophy, but also to offer a more profound meaning to Weichai products' “high reliability”.

High-quality castings create highly reliable engines

At the Fair, the castings of Weichai Power (Weifang) Casting Co., Ltd. and Weichai Binhai Foundry had a stunning debut.

Weichai Power (Weifang) Casting Co., Ltd. showed its WP9H, WP12 Landking cylinder block blanks, WP4/WP7/WP9 integral cylinder heads, gear chamber and transmission case castings.

Weichai high-quality castings attracted many guests

The WP9H rough cast is made of high grade cast iron, in order to meet the demands of high-reliability of 1.8 million km / 30,000 hours and high PFP of 20MPa pressure. The tensile strength of the cylinder block body should reach 250MPa, and the tensile strength of the integral cylinder head with the air intake pipe should reach 300MPa.

The strong engine block that can support an engine life of up to 1.8 million kilometers / 30,000 hours

In addition, the WP7 cylinder head blanks and Baudouin M26 engine block represented the mass-production quality level of Weichai vermicular iron castings.

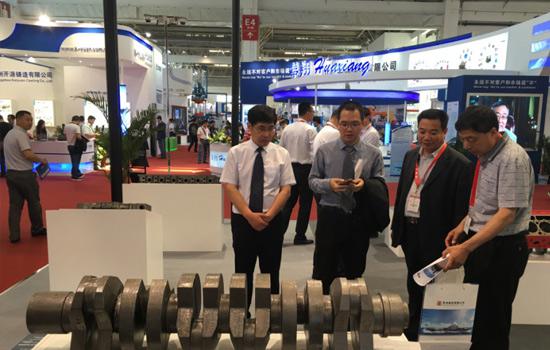

At the fair, Weichai Binhai foundry showed their casting products, such as Baudouin V-type M26 cylinder blocks and 6170 crankshafts.

6170 crankshaft casting by Weichai

It is understood that Baudouin’s V-type M26 cylinder block is made of cast iron, and has the grid structure, high strength, and good cooling effect. The 6170 crankshaft is of high grade and large size. The advanced production technology ensured that the cast ductile iron crankshaft rejection rate is below 1.5%.

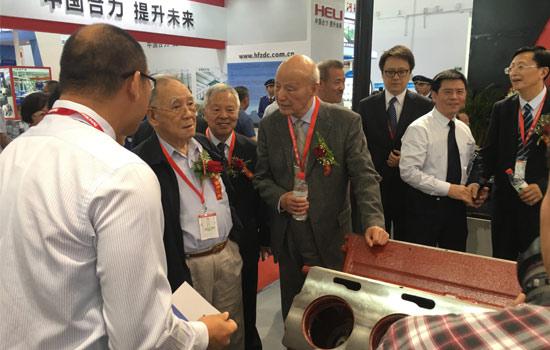

After winning praises from industry experts for Baudouin V-type M26 cylinder block castings, Weichai is encouraged to make greater contributions for the casting industry

Weichai’s "Green Casting" leads the industry to be more environmentally friendly

Weichai Power (Weifang) Casting Co., Ltd. has the annual production capacity of over 350,000 tons of castings, covering key engine parts of gray iron, vermicular iron, ductile iron and other materials. The pass rate of main products is stabilized at 97%, reaching industry advanced level. The products are mass supplied in internal combustion engine, transportation, construction machinery, energy, chemical, environmental protection and other industries.

The company has processes with cupola (35t) / duplex melting furnace and electric furnace smelting. There are also 8 KW and HWS fully automated molding lines, 11 sets of imported core making centers, and DISA shot blasting cleaning equipment.

The 35T oxygen-rich water-cooled long-lasting cupola furnace lookout in Weichai casting

The fully automated molding line in Weichai casting

Weichai Casting core making centers

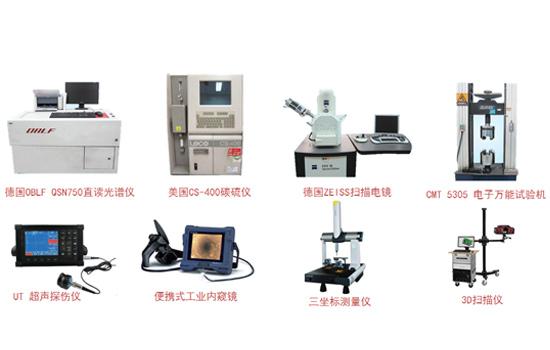

The company has achieved comprehensive system certifications, and has 137 units of equipment for raw material, mechanical property, size and metallurgical testing, which allow the company to monitor the whole process from material acceptance, production process control, to casting inspection. The casting process development uses specialized software to achieve high efficiency and paperless design. The casting simulation workstations are used to simulate, analyze and optimize the casting processes.

The extensive testing equipment of Weichai Casting

Weichai Binhai Foundry has 6 electronic furnaces and two of the largest engine block body and crankshaft resin sand molding line with highest degree of automation. They can produce large diesel engine block blanks up to the weight of 70 tons.

The largest crankshaft resin sand molding line in China at Weichai Binhai Foundry

Starting from the planning and construction to the production process, Weichai Binhai Foundry has always adhered to the "lean" and "green" philosophy, and follows the "responsibility-oriented" management model, to build China's largest and greenest medium-speed engine casting production base in China.

Weichai Binhai Foundry’s advanced melting workshop equipment with environmental friendliness