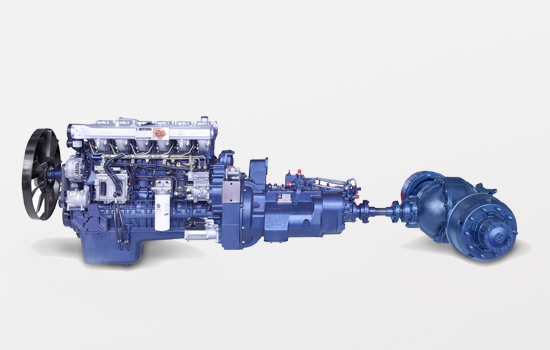

(Weichai Powertrain)

As the state's stricter emission regulations and customers' higher demands for vehicle cost, performance, fuel consumption and other aspects, modern heavy trucks are facing higher requirements. But as of right now, the work-alone nature of vehicle part companies in the industry cannot maximize concerted efforts to support the vehicle to achieve the best performance, and the work-alone nature has been difficult to adapt to the development of modern industry. Especially in recent years, intelligent vehicle driving and intelligent powertrain control technologies have made great progress, which allows the relationships between parts, assemblies and vehicle, closer and closer. This has brought an urgent need to integrate the upstream and downstream industries together with a bottom-up or top-down fashion in order to better achieve system matching and generate concerted efforts to reduce costs and improve performance. Many excellent commercial vehicle groups, such as Daimler and Volvo, all have a top-down integrated industrial resource chain including vehicle, powertrain and parts. The recent MAN and Scania cooperation to develop MAN’s own transmission also fully explains the problem.

Advantages of the powertrain

Powertrain is the core of commercial vehicles. The power, economy, comfort, cost, reliability, safety and environmental protection of the vehicles are related to the powertrain.

Specifically, intelligent matching technology can be used in the powertrain integration process to improve vehicle performance and make the engine, transmission and axle selection and matching more reasonable. It can also effectively reduce overall vehicle fuel consumption when it comes to improvement of the power performance. Using thermal management, CFD simulation, and powertrain NVH optimization can greatly enhance the vehicle driving comfort. Intelligent control of each subsystem's communication and collaboration can significantly extend the powertrain's work life to improve the vehicle's reliability.

Powertrain allows the parts to have a unified management system based on market demand, so that effective production capacity safeguards can be made. Fuel consumption reduction, quality improvement and guaranteed maintenance and service significantly reduce customer's use, maintenance and repair costs, thereby reducing the vehicle life-cycle cost and bringing more economic benefits to the customer. This way, the advantages of powertrain becomes the company's core competitive advantages.

Weichai, the "first mover"

In the industry, Weichai is one of the earliest companies to start building the core competitiveness of the powertrain businesses. Back in 2005, Weichai acquired Torch to integrate the quality resources in the vertical industry chain, and established the vision of "build an international enterprise with core powertrain technology guided by vehicle business, and become a unique key player in the global equipment manufacturing industry".

With the most complete R&D and manufacturing systems for commercial vehicle diesel engine, transmission and axle, Weichai has the strength and heritage towards this goal.

As the most influential heavy-duty engine brand in the country, Weichai engine's market share has been the industry's first for a long time. Weichai has strong R&D strength, a team of talent, and complete product lines that consist of vehicle engines with displacement from 2L to 13L. Weichai established Weifang, Shanghai, Yangzhou, Hangzhou and Chongqing five R&D centers in China, as well as R&D institutions in the United States, France, Germany and Italy.

Currently, Weichai owns the modern test center that has five-axis power system test benches, vehicle chassis dynamometer, high-pressure common rail fuel pump test benches, extreme environment test chambers, CVS full flow test systems, tilt test benches, friction testers, transmission test stands, axle fatigue test benches, gearbox test benches, etc., to carry out be powertrain, engine, transmission, axle and other component tests. Weichai also has a well-equipped pilot production plant with 83 sets of test equipments from world-class manufacturers. A highly qualified powertrain R&D team of near 300 engineers has a wealth of experience in product development and engineering.

All these work made the blueprint of the powertrain blueprint flesh out. Through the cooperation with the European R&D centers, AVL vehicle research and development center as well as domestic and foreign automobile industry-renowned experts, the technical elites of Weichai, Fast, Hande Axle spent six months and more than 20 million RMB, and launched the first commercial vehicle powertrain in China at the end of 2007. The product had gone through rigorous testing and demonstration match, and it had outstanding performance in all aspects, which could be called the best power system solution in China in terms of power, economy, reliability, etc.

Take-off on the new platform

Starting from 2009, Weichai Power applied for the establishment of "National Commercial Vehicle Powertrain Engineering Technology Research Center" which has now passed the acceptance and has been formally estblished. With this platform, Weichai undertook and completed a number of National Science and Technology projects, including truck powertrain system development and tractor powertrain system development.

The truck powertrain development project included to first equip the WP5 China V engine on the truck, comprehensively test and research the truck powertrain, achieve a comprehensive fuel-saving rate of 12.75% -14.22%, reach the China V emission level, and succeed in application on the new Shacman M3000 heavy truck. The project filed a total of six invention patents, and allowed the company to master truck powertrain optimization method and development process, thus establishing the Group’s gold industrial chain of truck powertrain.

During the development of tractor powertrain, Weichai R&D staff comprehensively tested and researched the tractor power system and allowed the tractor to save 13.75% of fuel while remaining the same power performance. The project declared six invention patents and let Weichai master the tractor powertrain optimization method and development process, establish a high-quality team of talent, and improve the collaborative development capabilities of Group subsidiaries in a project.

Inside of the Group, Weichai optimized the matching among the engine, gearbox, axle and other powertrain components, as well as the intake and exhaust system, cooling system and suspension system based on Yaxing bus development planning, to improve competitiveness of Yaxing buses. The 12m intercity bus powertrain matching technology research project also had a breakthrough, declaring four invention patents and reducing fuel consumption by 10.49% while gaining the same power performance as the benchmark products. The YBL6125H2QJ full-load highway luxury bus equipped with optimized powertrain developed through the project won the best highway bus award on the road in the "2012 Beijing international road transport and urban public vehicle parts exhibition". Weichai's Shacman heavy truck also achieved a breakthrough on reducing fuel consumption with existing powertrain. The project team tested and researched seven current typical Shacman heavy trucks, and brought out the optimal powertrain configuration. They focused on the X3000 tractor to determine the typical customer, extract usual operating conditions, develop applications, perform multiple dyno tests, customize the optimal configuration for typical customers, and finally carry out the validation test for customers. The project researched the powertrain through a closed loop and allowed the vehicle fuel consumption cycle to decrease 3.33L/100km.

Future directions

For the future, the core of a new breakthrough in vehicle performance is the powertrain. But for the moment, the advantages of powertrain need further development, and Weichai planned to do more on driving efficiency and modularity.

A large part of the powertrain performance depends on efficiency of the transmission system. With faster urbanization, faster transportation is an inevitable trend. As the key assemblies in the commercial vehicle chassis, the high efficiency and high technology of engine, transmission and axle will improve transport efficiency and reduce logistics costs. In the future, high efficiency and high technology can be achieved in terms of engine performance, transmission NVH performance, gearbox transmission efficiency, axle deceleration type, wheel braking type, and brake energy recovery.

Facing the increasingly stringent emission regulations, a single component or system has little room to develop, but modularity and integration of the powertrain system have become the focus of one of the future direction of development work. Modern electronic control technology and CAN bus technology enables powertrain to become an inseparable whole. Through the integration and optimization, engine, clutch, transmission, axle and other sub-assemblies can significantly improve the overall performance of commercial vehicles to make them safer, more reliable, and more environmentally friendly.

Dr. Haoran Hu, Vice President and CTO of Weichai Power